Urgence gaz 0 800 028 800

Gas transport projects: taking a pipeline from research to operation

As a regional and national player in the energy market, Teréga has built up more than 75 years’ expertise in the development and operation of gas transport and storage infrastructures. Within that sphere, we continue to invest in enhancing our infrastructures, keeping our network safe and well-maintained, and for the past few years we have been developing projects around renewable gas supplies. All these projects have the same aim: to provide everyone with an ever safer, more efficient and environmentally integrated network. To that end, every gas transport project goes through the same well-regimented stages, from initial research to construction, and on to operation.

Before construction starts: joint planning and design

The design of new infrastructure is an essential phase of a gas transport projects and a key part of our expertise. So whenever new structures are developed, we compile an application for permission to construct and operate (DACE), which is sent to the Prefect of the appropriate geographical Department, or to the relevant Minister when a project covers tens of kilometres.

The application involves:

a hazard assessment;

an environmental assessment if appropriate;

a consultation with the authorities;

and possibly a public inquiry.

At the end of the process, once the application has been passed by the Departmental committee for the environment and health and technological risks (CoDERST), a permit to construct and operate the pipeline is issued. The Prefect or Minister may also declare the work to be in the public good if such a request is submitted by the transporter.

The 3 essential phases of designing a project

1 - Study

The hazard assessmentIts purpose is to assess and set out the risks that could be presented by the structure and any risks associated with its environment. During this study, we define, determine and justify measures which will be taken to reduce the likelihood of such hazards occurring and the effects of any accidents. They are approved by the authorities and it is our responsibility to ensure they are implemented.

2 - Assessment

The environmental assessmentThis sets out the initial state of the physical, natural and human environment of the proposed structure. In it, we justify our choice of route and present an assessment of the temporary and permanent effects of the project on the environment. This assessment draws on fauna and flora assessments conducted by ecologists and covering all four seasons. From this phase onward, we apply the “AVOID - REDUCE - COMPENSATE” approach at all levels of our organisation, driven by our environmental programme: BE POSITIF.

3 - Inquiry

The public inquiryThis may be tied into the application for permission to construct and operate. It takes place once consultation with the authorities has ended, and cannot be shorter than one month or longer than two months. We are committed to considering the views, suggestions and counter-proposals we receive.

Teréga’s up-front commitments

We study development opportunities for the areas we cover well in advance. Our responsible approach is guided by these principles:

to give local dialogue top priority, to talk to and involve local stakeholders (local authorities, chambers of commerce and industry, energy syndicates, elected representatives, neighbours);

to encourage training and access to the labour market through our projects;

to participate in the emergence of new projects (biomethane, roll-out of digital services across the area, connection of new public distribution grids etc.);

to facilitate positive economic outcomes for the area during the work (equipment hire, local recruitment etc.). We also prioritise the engagement of local and regional contractors.

In fact, as a responsible player in the gas industry, we are aware that any gas transport pipeline project involves facing a number of challenges: land ownership, urban development, safety of work and structures, town and country planning, care for the environment and natural areas being crossed etc.

To that end, we rely on a tried and tested methodology with three main principles:

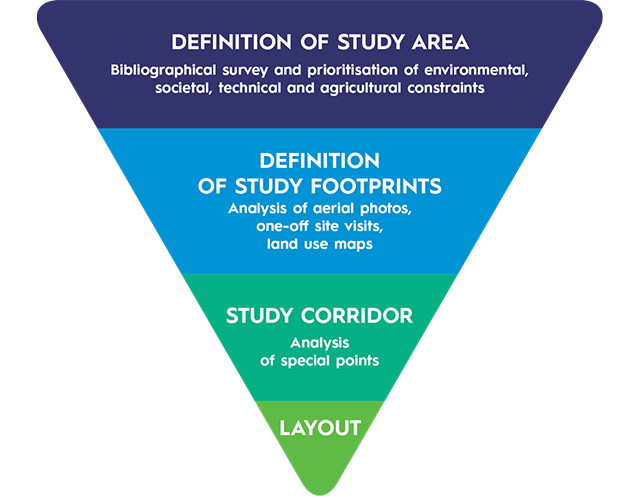

To satisfy the requirements of the legislation, we consider environmental and safety aspects from the start of the “pre-project” phase. Avoiding the main challenges is part of the conceptual study phase, following the analysis of a wealth of incoming data (regulatory zoning, identification of urban development, inventory data gathered from various bodies or associations, aerial photographs) which constitute the starting point for the so-called “funnel” approach.

With 4 major projects undertaken in the far South-West since 2010, we have developed unique expertise in protecting the environment and human activities.

Working in successive sections (an individual plot is occupied for just a few weeks),

Work schedule arranged around the biological cycles of the species found there,

Watercourses maintained,

Disruption to agriculture minimised and compensation paid for damage to crops.

When the impact is not deemed to be negligible, we propose compensatory measures in proportion to the challenges. In particular this involves the acquisition and protection of spaces for the improvement or recreation of protected natural environments. This important stage is a major contributor to us achieving our aim of having a positive environmental impact, with our BE POSITIF (positive environmental outcomes) programme.

An inverted pyramid based on the “AVOID - REDUCE - COMPENSATE” methodology

The method for defining a route involves:

identification of the geographical area,

mapping of human, safety, environmental and social challenges,

research into opportunities for new projects (biomethane, roll-out of digital services, connection of new public distribution grids etc.);

assessment of different routing options,

assessment and recommendation of the corridor,

choice of the route presenting the best opportunities for the area.

During construction: work in accordance with the safety challenges

Very carefully monitored work

The work of laying a pipeline is carried out by specialist companies. They are subject to very strict safety rules to protect property and persons. This work is covered by approval and control procedures imposed by the authorities and by our teams.

A fully protected pipeline

Our pipelines are protected against corrosion by a special external coating and by cathodic protection (an arrangement that prevents the effects of corrosion). A coloured warning mesh is laid above the pipeline to provide a visual warning of the structure’s presence in the event of works. Protective slabs may also be put in place in certain locations, in accordance with the recommendations of hazard studies, to protect against external damage.

Burial depth greater than that recommended by current regulations

While the regulations define a minimum depth of 1 metre, regardless of the location of a pipeline, for the last 15 years or so, we have always looked to bury new pipelines to a minimum of 1.20 metres.

Monitoring, maintenance and inspection of the grid during the operating phase

Ongoing monitoring of our pipelines

Each pipeline that is in service is covered by a dedicated programme including in particular:

remote monitoring 24/7;

aerial survey of the pipelines at least 10 times a year;

survey of the route on foot or by vehicle every two years;

pipeline inspection every 10 years.

Safety measures that adapt to development of the area

Every five years, we update the hazard assessment for the whole of our network. We also identify areas subject to regulatory improvements (laying of protective slabs, enhanced marking etc.).

Safety: a priority for everyone

In accordance with regulations, we establish our Safety and Intervention Plan and communicate it to the public authorities. It defines:

safety and control measures;

organisation of the emergency response in the event of an accident.

Effects limited to the construction phase

A pipeline project is organised to take other uses of the land into account as much as possible. We therefore make sure those who own and work on the affected plots are closely involved.

A condition of premises report is drawn up before and after the work with each party, with a view to signing an amicable easement agreement.

Once construction is over, unless particularly requested by the landowner, we restore the plots to their original state. The only visible vestiges of the work will be a few markers to indicate the buried pipeline.

The land can then be farmed once more, but the planting of tall trees (> 2.70 m) and the construction of buildings remain prohibited during while the routing and operating easements remain in force.